Raisecom Industrial Switches Awarded from Guodian Nanjing Automation Co., Ltd. Procurement Bid

Raisecom Gazelle S series industrial switches adopt industrial-grade chips and power modules, low power consumption design, and have strong reliability and good anti-electromagnetic interference performance.

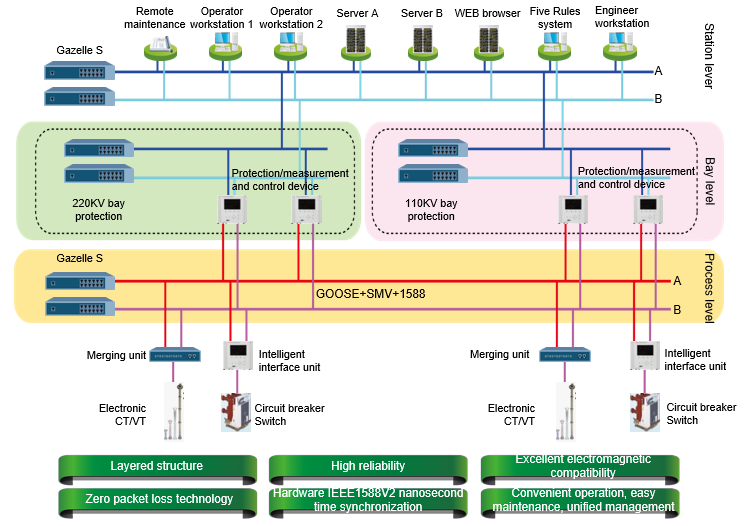

In recent years, along with the continuous development of computer and communication technology, the power system has also increased the requirements for the digitization and networking of power equipment. The integration between intelligent primary equipment and networking secondary equipment has already become the main trend in the future development of substations. The new substation automation standard IEC61850, which includes substation control level, bay level and process level, makes "Smart Substation" gradually come into people's field of vision.

Generally, the smart substations adopt merging units to take data transmission of digital sampling value in process level, and rely on GOOSE messages to transmit primary equipment status and control commands. Under this background, in addition to carrying the traditional station communication services, the industrial switches have begun to replace traditional cables and become the central equipment connecting the primary and secondary equipment. The change in role and importance makes industrial switches used in smart substation face a harsh and complex operating environment. The performance and reliability of industrial switches directly affect the safe operation of substations.

Due to the continuity and significance of power production, the reliability of communication network in the station is the most important. It is necessary to avoid communication interruption caused by device failure. Raisecom Gazelle S series industrial switches comply with IEC61850 standard, which can form a double-star network to ensure the accurate synchronization of sampled measured values in the process level, and provide a clock synchronization solution accurate to IEEE 1588 v2 nanosecond level in the IEC 61850 process level.